High-Purity Manganese Sulphate Monohydrate (HPMSM)

Black Canyon Achieves Battery Grade Manganese Sulphate

Black Canyon successfully completed hydrometallurgical testwork on manganese oxide samples from the KR1 deposit, within the Balfour Manganese Field (BMF). Results generated High Purity Manganese Sulphate Monohydrate (HPMSM) meeting battery grade specification of >99% HPMSM Purity and within specification impurity levels.

Producing Battery Grade HPMSM is a major milestone achievement for Black Canyon. The HPMSM strategy is strongly supported by the evolution of Li-ion batteries and specifically cathode chemistries with battery technology developers increasing safety and energy density from more readily available materials, which includes higher manganese content across a growing range of battery platforms.

Manganese (Mn)

Manganese has traditionally been used in steel manufacturing with manganese alloys added to prevent corrosion, resist abrasion, and increase hardenability. This consumes approximately 90% of the manganese produced globally. The balance is used in a number of different applications such as High Purity Manganese Sulphate Monohydrate (HPMSM), a critical raw material in the production of lithium-ion batteries used in the Electric Vehicles.

High Purity Manganese Sulphate Monohydrate (HPMSM)

High purity manganese products are essential materials needed by the EU’s fast-growing electric vehicle and lithium-ion battery industries. The term “High-Purity Manganese” (HPM) refers to a suite of highly refined finished products that are critical to most lithium-ion batteries. Its use and demand are increasing rapidly, particularly in Europe, China and the US.

Expanding Electric Vehicle Market

The electric vehicle market has witnessed remarkable growth in recent years, driven by increasing environmental awareness, government incentives, and technological advancements. EVs are becoming an increasingly popular choice among consumers, leading to a surge in demand for lithium-ion batteries, in which HPMSM plays a vital role.

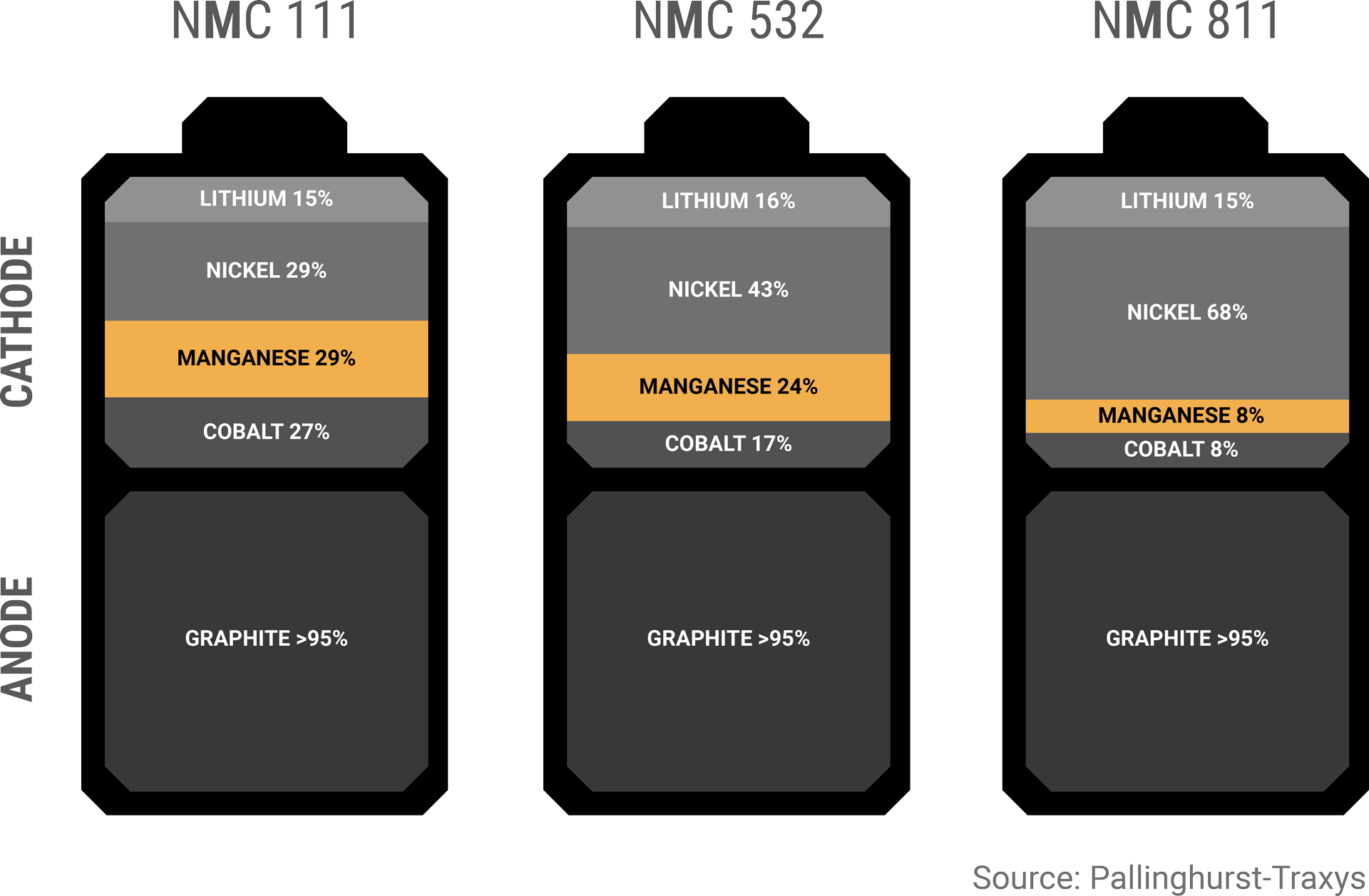

Manganese is used in the cathodes of lithium-ion batteries, and as the EV market expands, so will the demand for these batteries. The choice of battery technology platform by EV manufacturers can influence demand for manganese sulphate, as shown below with the manganese contribution varying between 8% and 60%.

Ternery (NMC) Li-Ion batteries

The demand for HPMSM for electric vehicles is expected to grow in line with the expansion of the EV market, which is driven by environmental concerns and efforts to reduce greenhouse gas emissions. Additionally, the availability of sustainable and responsibly sourced manganese will be a key consideration for both producers and consumers in the EV supply chain.

Europe, North America, Japan, Korea and many other countries import 100% of their manganese requirements, including high purity electrolytic manganese metal (HPEMM) and HPMSM, which are essential materials used in the production of lithium-ion EV batteries.

HPMSM Strategy Rationale

In an increasing number of EV battery compositions, manganese is used in the cathode and makes up a significant proportion of the battery volume. Manganese sulphate monohydrate is commonly used in lithium manganese oxide (LMO) and nickel manganese cobalt (NMC) battery chemistries with the manganese contribution varying between 8% and 29%. The introduction of the manganese into LFP batteries (LFMP), high manganese iron-nickel and high lithium manganese compositions will likely see further demand for HPMSM.

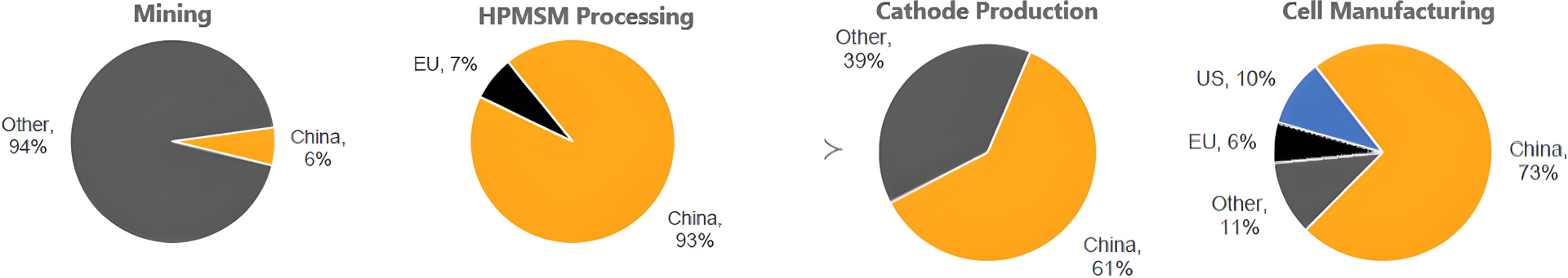

Currently, China dominates the HPMSM market, with over 90% of global production. Similar to other cathode precursor materials, the requirement for security and diversification of supply will become a significant factor inducing the establishment of additional supply outside of China, primarily for the American and European car manufacturing industries. The US Government has a critical mineral list that the Biden Administration identified as critical for domestic energy, electronics and defence that includes manganese. The Inflation Reduction Act recently approved by the US Government and the Free Trade Agreement between the US and Australia enables direct US investment into Australian critical mineral projects and will substantially incentivise electric vehicle and clean energy industries to establish operations in the US. This has continued to positively impact US and European investment in the development of new cathode or battery pack production capacity in parallel with joint ventures between automakers and battery manufacturers to meet growing EV demand. The potential benefit to Black Canyon is the rapid expansion of the manganese sulphate market beyond China and an interest in gaining access to long term physical supplies of manganese from a Tier 1 location like Australia.

The future of HPMSM in the electric vehicle market appears exceptionally promising. Its role in lithium-ion batteries, sustainability in sourcing, ongoing research & development and government support all contribute to a positive outlook. As the electric vehicle market continues to grow, HPMSM is positioned as a vital component in the sustainable and efficient electrification of transportation.

Production of HPMSM

High Purity Manganese Sulphate Monohydrate is typically produced through a multistep chemical process that involves the extraction and purification of manganese-containing raw materials. The manufacturing process begins with the crushing and beneficiation of the manganese ore to extract the manganese mineral content. Once extracted, the ore is subjected to a series of chemical treatments to remove impurities such as iron and other metals. These impurities are separated through processes like leaching, precipitation, and filtration. The resulting manganese solution is then further purified to achieve the desired level of purity.

After purification, the manganese solution is typically subjected to a crystallization process to form manganese sulphate crystals. This involves cooling the solution to induce crystallization while maintaining the appropriate chemical conditions. The addition of water during this process leads to the formation of manganese sulphate monohydrate, which contains one molecule of water for every molecule of manganese sulphate. The monohydrate form is particularly useful because it provides a stable and easily handled product. The crystals are then harvested, washed, and dried to remove excess moisture, resulting in the production of High Purity Manganese Sulphate Monohydrate.

Black Canyon’s Expanded HPMSM Strategy

Black Canyon has a dominant tenement position in the Pilbara Region of Western Australia. The Company has methodically increased its resource inventory, with a Global Mineral Resource across the Balfour Manganese Field now totalling 314 Mt @ 10.5% Mn containing 33.1 Mt of manganese. A higher-grade component has been delineated, which totals 99 Mt @ 12.9% Mn containing 12.8 Mt of manganese.

The HPMSM strategy is strongly supported by the evolution of Li-ion batteries and specifically cathode chemistries with battery technology developers increasing safety and energy density from more readily available materials, which includes higher manganese content across a growing range of battery platforms. It is an exciting space as the demand for HPMSM is expected to continue over the coming decade with limited non-Chinese supply options. Western OEM supply managers have been very active in the lithium and nickel space, reflected in several transactions across a range of Australian and Canadian based projects. It is only a matter of time before the level of interest in manganese, particularly manganese sourced from Australia accelerates and Black Canyon is positioning itself to be ready for this demand.

The expanded HPMSM testwork has been applied to manganese oxide materials gathered across the Balfour Manganese Field, where the Company recently completed successful maiden RC drilling programs to establish Mineral Resource potential. The identification of higher-grade manganese mineralisation that is outcropping or close to surface provides optionality for the development of standalone HPMSM feedstocks that may be permitted relatively quickly due to the potential lower impacts of a small footprint operation.”

The hydrometallurgical leaching and planned multistage purification stages should continue to demonstrate the amenability of manganese oxide ores to downstream processing. The technology to purify oxide ores has been established across other hydrometallurgical applications and the Company continues to investigate several methodologies with the aim to minimise complexity where possible, potentially reduce CAPEX and define a reliable cost-effective flowsheet design.”

The Company is seeking to develop a low CAPEX, low impact mining facility that could be permitted and approved relatively quickly. This would potentially reduce the timeframes for Black Canyon to supply manganese oxide feedstock to a downstream HPMSM facility. Black Canyon has commissioned experienced environmental and approval advisors, Preston Consultants, to advise on the likely environmental studies, approvals and timeframes required for a campaign-based mining operation utilising simple beneficiation processes to upgrade the manganese oxide materials in preparation for hydrometallurgical processing into HPMSM.

If the testwork and studies indicate that it is commercially viable to produce HPMSM, the Company will progress its activities, including larger scale pilot testwork and discussions with potential offtakers and funders.